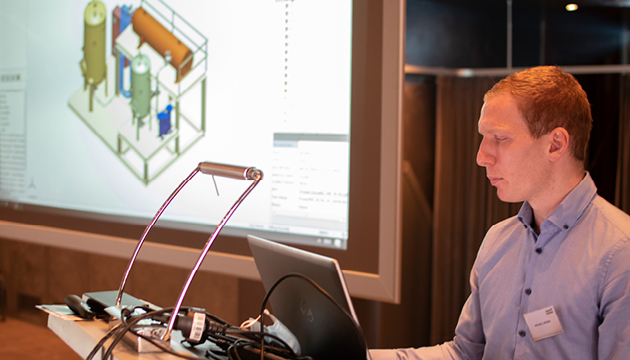

Together with Pipe Bending Systems GmbH & Co. KG, Polysoude Deutschland GmbH, and König Maschinenhandel GmbH, Smap3D Plant Design GmbH presented a holistic plant design solution that covers all processes of pipe design, manufacturing and machining, starting with 2D flow diagrams up to bending, orbital welding or collaring of pipes. The overall solution was shown during the Plant Design & Piping Production World 2021, which the four partners jointly hosted on September 7th.

The thematic focus of the event in Lennestadt-Meggen was digitalization and its actual relevance for mechanical and plant engineering, pipeline planning and pipeline construction, which was highlighted in theory and in practice. The solution presented pursues the Industry 4.0 approach: it bundles the profound experience gathered by the four companies and thus enables an integrated complete solution for plant engineering in which all systems communicate with each other and exchange data. "By networking the individual areas along the entire value chain, companies with batch and small-series production are already able to design, manufacture and process pipes and pipelines more cost-effectively, more quickly and with higher quality," explained Dr. Christian Gerlach, Managing Director of the host company Pipe Bending Systems (in short: PBS).

For the design of pipes and pipelines, Smap3D Plant Design GmbH offers a sophisticated software package with which 2D flow diagrams (P&ID), 3D piping design and isometric drawings for pipeline production can be implemented. It can be seamlessly integrated into the CAD systems Solid Edge, Solidworks and Inventor. In addition, integrated bending simulation allows feasibility checks to be performed during the design phase. "Smap3D Bending Simulation links design and manufacturing and provides the necessary security for pipe production, which significantly optimizes and accelerates the overall process," said Maxim Lich, CEO of Smap3D Plant Design. An interface is then used to transfer the relevant design data to PIPEFAB, a software for process planning and control. This solution from Pipe Bending Systems links the target data from CAD with organizational data from ERP (e.g. master/order data) as well as technology data (e.g. welding gap) and stores the digital manufacturing process in the database. In this way, specific information can be generated for pipe preparation and processing. In addition to data for the PBS bending machines, welding parameters for TIG orbital welding with products from Polysoude GmbH are also provided. The circumferential welding equipment and welding heads, which enable high-quality welded joints, thus have all the necessary information they need and once the welding task has been performed, they can feed the data back into the ERP or PIPEFAB for documentation. The T-Drill collaring, flanging and pipe cutting machines for chipless cutting presented by König Maschinenhandel also benefits from the end-to-end processes: The digitized, partially automated assessment of feasibility studies provides security for the subsequent production, and transfer of relevant data to the machines and ensures more efficient work processes. If the T-Drill and Polysoude machines are combined, plant manufacturers save time and costs, because the process results in fewer welds on the pipes and eliminates the need for time-consuming reworking of the welds.

In addition to presentations of the individual solutions in the extraordinary grounds of the Sauerland Pyramids, participants were also able to visit the in-house exhibition at the plant of nearby Pipe Bending Systems, where the four partners presented their products in live operation and addressed explicit questions from the participants.